Every quarter, we like to zoom in on a specific sector. In doing so, we take a close look at what lifting aids exist for optimising the specific handling processes. This quarter, we have chosen the beverage industry. This is an often underexposed sector within the food industry.

In the production process, there are many similarities with the classic food companies. Raw materials are packed in barrels or bags. This is where the classic lifting systems come in. Many food companies already use these solutions. Just think of the vacuum bag lifting system, where bags are lifted and moved by means of vacuum. In this way, they can be emptied into a reactor or a tub in an ergonomic way. The same applies to tipping out raw materials into containers. Here, mobile lifting devices are more often quoted.

So how does the beverage industry differ from the food industry? This is mainly reflected in the way the end product is packaged. Whereas traditional food products are more often packed in bags or boxes, it is logical that drinks are mainly delivered in bottles or barrels. This creates the specific handling challenges that we will come back to in this post. Below is a non-exhaustive list of lifting applications in the beverage industry.

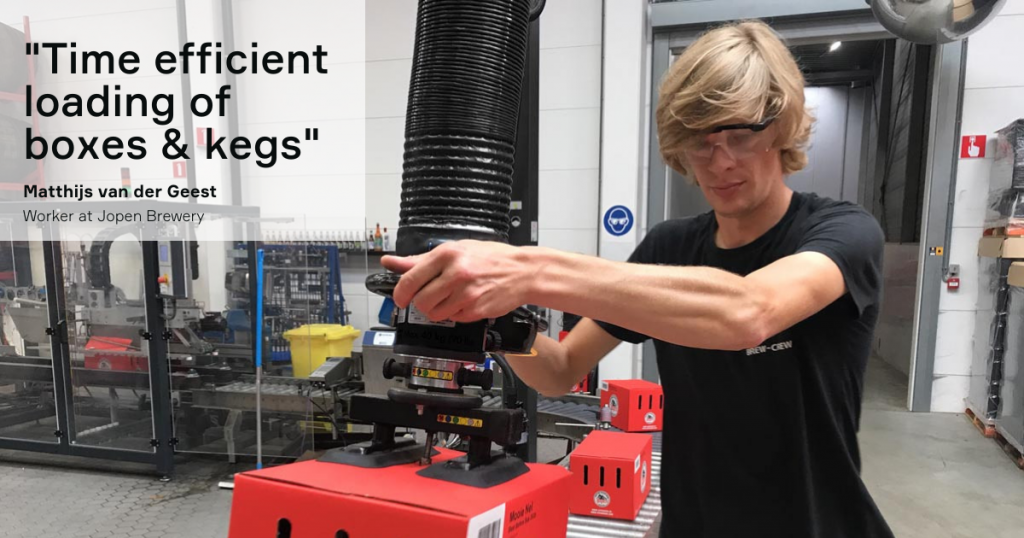

Lifting boxes

Bottles are not always transported in crates for export, but very often in boxes. These boxes are heavier, because glass naturally weighs more than traditional packaging materials such as plastic and paper. This makes the boxes more difficult to handle. The vacuum lifting system for boxes has become a must-have for this application. In the picture below, made in a Dutch brewery, you can see a satisfied operator palletising the filled boxes.

Lifting crates

At first sight, the vacuum lifting system seems to be a less obvious solution for manipulating containers. However, nothing could be further from the truth. We do not necessarily need a large and flat suction surface in order to work with crates in a smooth manner. The fast-acting tube lifter system, combined with the adapted side lifter with hook, ensures a flexible and smooth manipulation.

Tilting of beer kegs

A recurring phenomenon that we see in breweries is that beer kegs are filled upside down. This complicates the handling process. Not only does the operator have to carry the full 30 kg of the keg, but he also has to tilt it 180°. This new variant of the vacuum lifting system is an excellent solution for this, according to the many breweries that are already using it.

If you are active in the beverage industry and have certain lifting applications that are not included in this article, please leave a short message using the contact form.

Repackaging in tailor-made plants

The beverage industry works closely with tailor-made companies. These companies put together promotional campaigns or carry out repackaging activities. These lifting aids can be used very well in these environments.

Do ergonomics and efficiency go hand in hand?

Ergonomic lifting solutions can count on pros and cons for many people, not least the operators themselves. Many people think that an ergonomic lifting device must come at the expense of efficiency in the production process. But nothing could be further from the truth. Many successful customer cases confirm that with proper training and follow-up, productivity goes up. A win-win situation for operators and managers.

In addition, research has shown that the indirect costs are high in addition to the known costs of occupational accidents. On average, an accident at work costs 850 euros per day of absence. In case of a back injury, an operator is out of work for 2 weeks. This will cost you as a company at least 8,500 euros.